Reducing our carbon footprint

What do we report on?

Our carbon footprint reporting covers scope 1 & 2 emissions as well as business travel (scope 3) from companies in Belgium that are wholly owned by the Cordeel Group as well as the Cordeel subsidiary in the Netherlands. This organisational boundary is bigger than what we report on in the framework of the CO₂ Performance Ladder, which is currently focused on the operations of Cordeel zetel Temse as well as the companies located on our site “De Zaat” in Temse.

The emission factors we use to calculate our carbon footprint are the well-to-wheel emission factors that we use for the CO₂ Performance Ladder as well. These can be found at https://co2emissiefactoren.be/factoren

Due to the extended scope of companies we cannot report on the previous year for all the companies in the organisational boundary.

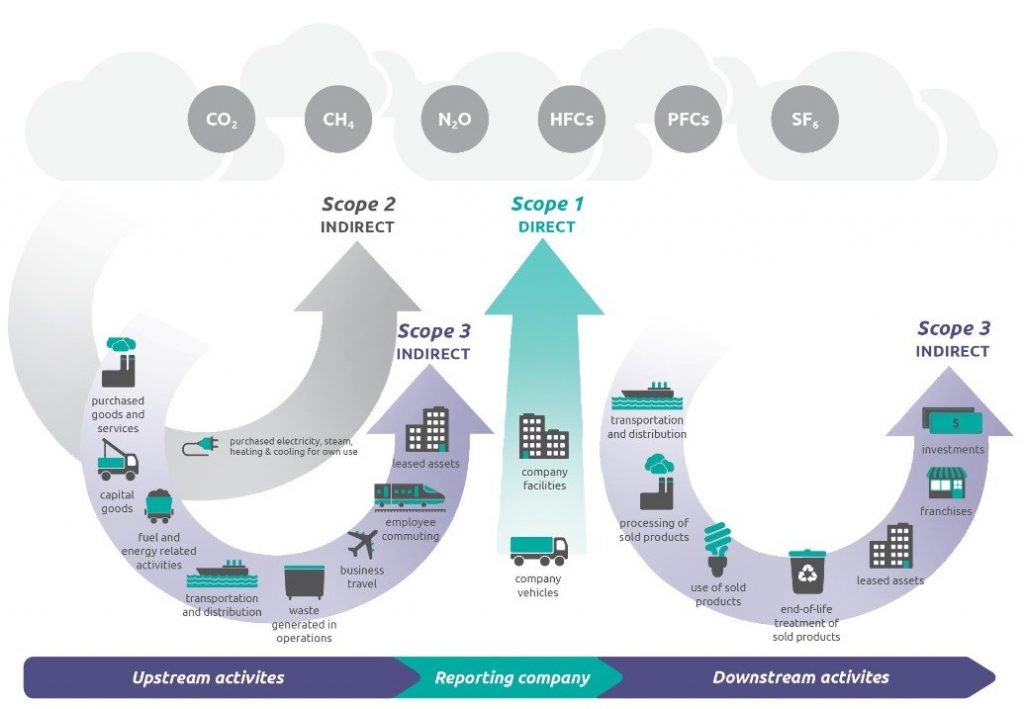

What are scope 1 emissions?

Scope 1 CO₂ emissions are direct greenhouse gas emissions that come from sources owned or controlled by a company, such as from our own vehicles, construction equipment or heating and cooling.

What are scope 2 emissions?

Scope 2 emissions are indirect greenhouse gas emissions that come from the generation of purchased electricity, steam, or heat consumed by a particular company or organisation. These emissions are generated by another entity, such as a utility company, but are a result of the energy consumed by the reporting company.

CO₂ Performance Ladder

The CO₂ Performance Ladder is a sustainability tool and certification scheme that empowers companies to reduce CO₂ emissions by implementing practical measures, fostering innovation and sharing knowledge. It is actively used as a criterion for awarding public contracts in the construction industry.

The idea behind the tool is to encourage the entire sector to establish a continuous management system for reducing CO₂ emissions, rather than working solely on project-based measures. As a result, the ladder delivers energy and cost savings for the company.

In 2021, the companies located at our site in Temse got certified at level 3 and we have been reporting on our CO₂ emissions and the progress since then. We aspire to achieve level 5, the highest level, during our upcoming re-certification in the summer of 2024.

Energy performance in 2022

*Measurement scope: Companies in Belgium that are wholly owned by the Cordeel Group as well as the Cordeel subsidiary in the Netherlands

| Renewable or not renewable? | Type | Sum of kWh |

|---|---|---|

| Non-renewable | Purchased electricity | 5,319,809.50 |

| Total not renewable energy | 5,319,809.50 | |

| Renewable | Purchased electricity | 2,779,233.00 |

| Self-generated energy | 1,685,957.00 | |

| Total renewable energy | 4,465,190.00 | |

| Total electricity consumption | 9,784,999.50 |

Energy intensity

*Measurement scope: Companies in Belgium that are wholly owned by the Cordeel Group as well as the Cordeel subsidiary in the Netherlands

| Consumption of electricity in MWh | Turnover in mio € | MWh per mio € turnover |

|---|---|---|

| 9,784.9 | 823 | 11.89 |

Temse as test case for our innovations on energy

With the C-energy division we accelerate the electrification of the construction sector, the operations of our customers and industrial processes. On the site of our headquarter in Temse, we test our innovations before go-to-market.

Currently, 2.07 Megawatts-peak (MWp) of solar panels are installed at our site in Temse. These solar panels reduce our dependence on fossil fuels and the grid, cut our carbon footprint, and are a prime example of how we are promoting renewable energy as an energy source of the future already today.

In 2022, we realised an auto consumption of 40% on our site “De Zaat” in Temse, which is a 10% increase compared to 2021.

We plan to structurally increase our auto consumption, e.g. with the planned battery storage projects on the site as well as the electrolyser that will be installed in 2023.

Our energy hill, which is expected to be completed in 2024 will provide additional energy storage.

Since the end of 2022, we have been testing and fine-tuning our EMS (Energy Management System), which is the backbone of all electrification projects. It is linking and steering our renewable energy production, HVAC system, batteries, charging poles and the to be installed electrolyzer and energy hill.

Energy target

Greenhouse gas emission performance

*Measurement scope: Companies in Belgium that are wholly owned by the Cordeel Group as well as the Cordeel subsidiary in the Netherlands

| Total CO2 emissions per scope | |

|---|---|

| Scope | Tons CO2 |

| 1 | 9,088.69 |

| 2 | 1,157.26 |

| 3 | 33.62 |

| Total | 10,279.57 |

-

19088.69

-

21157.26

-

333.62

-

Sport & pool facilities446

-

Offices/production1046

-

Fleet6535

-

Construction sites2219

-

Business travel34

GHG emissions intensity 2022

| CO2 emissions in tons | Turnover in mio € for companies in scope | Ton CO2 per mio € turnover |

| 10,279.57 | 823 | 12.49 |

| CO2 emissions by origin | ||

|---|---|---|

| Scope | Top category | Tons CO2 |

| 1 | Fuel | 8,223.09 |

| Heating | 793.96 | |

| Process gases | 1.61 | |

| Refrigerants | 70.03 | |

| 1 Total | 9,088.69 | |

| 2 | Electricity | 1,157.26 |

| 3 | Business Travel | 33.62 |

| Grand total | 10,279.57 |

-

C-tech3093.08

-

C-production154.73

-

C-living446.13

-

C-line4.35

-

C-energy10.24

-

C-construct6522.12

-

C2F148.93

CO₂ reduction targets

| 2023 | 100% green electricity for all locations |

| Roll-out mobile battery containers on construction sites | |

| Report on scope 1 & 2 of complete Cordeel group (reporting year 2023) | |

| Report on the three most material scope 3 emissions (reporting year 2023) | |

| 2024 | Ambition: Receive certification for CO2-prestatieladder level 5 |

| 2025 | Report on scope 1-3 of complete Cordeel group (reporting year 2025) |

| 90% of passenger cars are electrical | |

| 2026 | 100% of passenger cars are electrical |

| 2027 | Ambition: CO2-neutrality scope 1 & 2 with reduction of at least 75% (compared with base year 2022) |

Emission-free construction sites

Fossil fuels needed on our construction site account for 16.5% of our total CO₂ emissions. When zooming into our C-construct division, fossil fuels account for more than 25% of their CO2 emissions and are therefore an important driver of our scope 1 & 2 emissions.

To achieve our ambition of emission-free construction sites, we focus on their electrification. To achieve this, we apply the following measures:

Measuring consumption of electricity

With our C-scan sensors, we monitor electricity consumption of the main consumers on construction sites. The sensors offer us a transparent view of the electricity needed for tower cranes, dewatering of construction pits, and on-site offices, depending on the time of the year and phase of the works. This provides us with the insights we need to take the right reduction measures.

Electric construction equipment

Apart from using mobile battery containers to replace generators, we also invest in electric machinery. C-rental purchased five Volvo L25 Electric Wheel Loaders, which have the same power as a diesel-powered wheel loader but produce no emissions.

Furthermore, C-rental has integrated 70 electric scissor lifts and telescopic boom lifts into its fleet.

Use of biofuels

HVO100 is a synthetic biofuel under the EN15940 standard, consisting 100% of waste vegetable oils treated with hydrogen (HVO = ‘Hydrated Vegetable Oil’). It emits 89% less CO₂ over the entire life cycle (‘well-to-wheel’) compared to regular diesel.

Cordeel Nederland uses HVO 100 for every construction site, which makes up for a reduction of CO₂ emissions of 280 tons, based on the difference in CO₂ emissions of HVO 100 compared with conventional diesel.

We consider HVO 100 to be a transition fuel towards full electrification of construction sites.

Grid connection

Where available, we use a grid connection with as much power as possible.

Transport by water

Although we have not reported on our scope 3 emissions in a structural manner yet, we have been actively working on reducing them for a while. The strategic location of Cordeel Group headquarters alongside the Scheldt river provides us with the opportunity to use the river for our transportation requirements. This is not only efficient but also lowers our scope 3 emissions and helps us avoid the congestion of Belgian highways.

We also rely on water transportation to deliver raw materials for our concrete plant and the soil required to construct our energy hill in Temse.

Most of the prefab elements used to build the Amazon warehouse on the Blue Gate site in Antwerp were transported via water and picked up at our dry dock.

In Rotterdam, we’re currently building “De Boompjes” which is located right on the Maas river with the iconic Erasmus bridge in plain sight. By using water transportation, we were able to reduce 350 instances of traffic along congested roads in Rotterdam.

This approach is the ideal solution for inner-city buildings on the water. Not only did we significantly reduce truck traffic for residents and passers-by, but it also allows for the efficient use of the vessel to expand the limited construction site.

Mobile battery containers on construction sites

Since construction sites tend to have a limited or even no grid connection, this missing capacity is supplemented by diesel-powered generators. These have a negative impact on several environmental aspects such as noise, dust, nitrogen, ineffective fuel use, and high CO₂ emissions resulting from the use of fuel.

We noticed that we often use diesel generators with a capacity higher than required. The main reason is that tower cranes have power peaks for a very short period of time for which the capacity is dimensioned.

Our thorough measuring helped resize our mobile battery containers that will be rolled out in 2023. C-battery is producing these battery containers, based on lithium-ion technology and available in two versions, both built in 10ft containers: 100 kWh & 215 kWh.

C-rental already ordered 100 mobile batteries, which will also be available for third parties. In this way, we can not only decarbonize our own operations, but also support other companies in the sector to do so as well.

Eventually, these mobile batteries will make generators obsolete and have a major positive impact on the environment: less noise, less smell, less CO₂ and nitrogen emissions.

Greening the fleet

Fossil fuel plays a significant role in driving our CO₂ emissions. The fuel for our fleet accounts for 63.6% of our total CO₂ emission, a mere 6,532 tons. This makes the fossil fuel for the fleet the major driver of our CO2 emissions.

We’re actively tackling these emissions and expect substantial declines in 2023.

Charging poles

In 2022, we installed many new charging poles across our sites, bringing the total number of charging poles on our premises to over 60.

Powerstation, our charging pole supplier, is constantly expanding its range of charging poles available.

Their latest generation of charging stations will allow users to charge their vehicles without the need for a charge card or app thanks to the automatic authentication technology. Powerstation has plans to further develop a V2G (Vehicle-To-Grid) capability at a later stage, enabling vehicles to inject power back into the grid and serve as a driving battery for a variety of applications.

Fully electric car policy

In 2022, we have adapted our car policy to exclusively use 100% electric passenger cars to reduce our dependence on fossil fuels and lower our CO₂ emissions. In 2022 alone, we ordered 118 electric passenger cars, with plans to increase this number in 2023. No hybrid or fossil fuel powered passenger cars were ordered in 2022. However, one of the main challenges we face is the speed of delivery of the vehicles and the availability of suitable electric vans with a sufficient range, especially for the technicians at Imtech.

Hydrogen cars

We firmly believe in hydrogen’s potential as a sustainable energy carrier. We consider it a viable alternative for our bigger vehicles and for longer distances where battery technology may not be adequate.

Currently, we are running a pilot project using hydrogen-powered vehicles. To this end, C-energy purchased four Toyota Mirai hydrogen cars that are available as pool cars for employees who require transportation for site visits, customer appointments, etc.

In our Temse headquarters, we built our own hydrogen gas station. Our aim is to use the hydrogen that we produce through our electrolyser in this facility in the future.